Haha sometimes I used to think getting shipping to Canada was bad in terms of wait time, but I can’t even imagine what you guys go through

Hi folks

will be trying my samples this weekend, will keep you posted.

using an Upbox so should be fun

For some reason, my printer can’t extrude the PLA/PHA. It was fine with the PLA, but it’s just not working now. I tried raising the temperature to 235 C, but it doesn’t extrude. I pushed down on the filament manually, and it comes out fine, so I know my extruder isn’t clogged up. Any suggestions?

Any clicking noises coming from your printer when it tries to feed the filament through?

@tanya_Wiesner No clicking noises. The gear turn fine and doesn’t pause. It continuously spins like it’s supposed to do. And the filament only comes out as a little dot every few seconds.

Thanks

Caitlin

Curious. Maybe not enough pressure is building in the nozzle? Have you tried slowing the print speed down?

Also does the filament look stripped near the gear? If the gear keeps spinning with no filament going through try bumping the temp up again and/or slowing the print down at the same time.

Worst case scenario it may be time to clean out the nozzle tip. There could be some burnt crud that is sticking to the filament and preventing it from going through. I’ve seen it happen a few times in the past when I went from PLA to Ninjaflex. Ninjaflex woudn’t go through the nozzle properly because the nozzle had burnt PLA in it.

Hi Caitlin,

So sorry to hear that. Theoretically, every printer that prints PLA should print PLA/PHA and until know we haven’t heard of anyone having this problem. To troubleshoot, try printing with the PLA again. Also, what kind of printer are you using? This might help us to understand the issue better. My guess is that the hear is not making enough contact with the filament for it to be pushed down, since as you said it works when you pushed it manually.

Hey. I’m not sure if this is considered legal or not, since I was not part of this community when I did my review, but I ordered a spool of their black PLA/PHA and did a review of what I had. This is something I posted on my youtube channel.

Here’s the link: https://www.youtube.com/watch?v=EX9k5ROrYVU

What I don’t understand is why it wouldn’t extrude on all you’re printers, guys. I never had issues within the temp parameters. Not saying anyone’s doing something wrong, just confused myself.

Anyways, Yes, I was able to get it to extrude. My only changeup was I was overextruding at %100, so I dropped it down to %90, and everything comes out fine.

Can post some pics if anyone would like to see them.

Thanks.

Just my .02

So I tried to slow the print down to 20 mm/sec and rose the temperature till the filament was oozing out of the extruder as the extruder and bed were heating up. Once the printer started, it stopped oozing. I am so surprised and confused because this has never happened before. I built my printer with a kit from Geeetech.com and its a reprap prusa. I am using a MK8 extruder. I’m going to play around with the slicer settings to see if I can find the overextruding thing that @Mikethebomber was mentioning.

This is most likely not a filament problem, just a printer problem. I’ve been having so many issues lately with the printer and customer service…

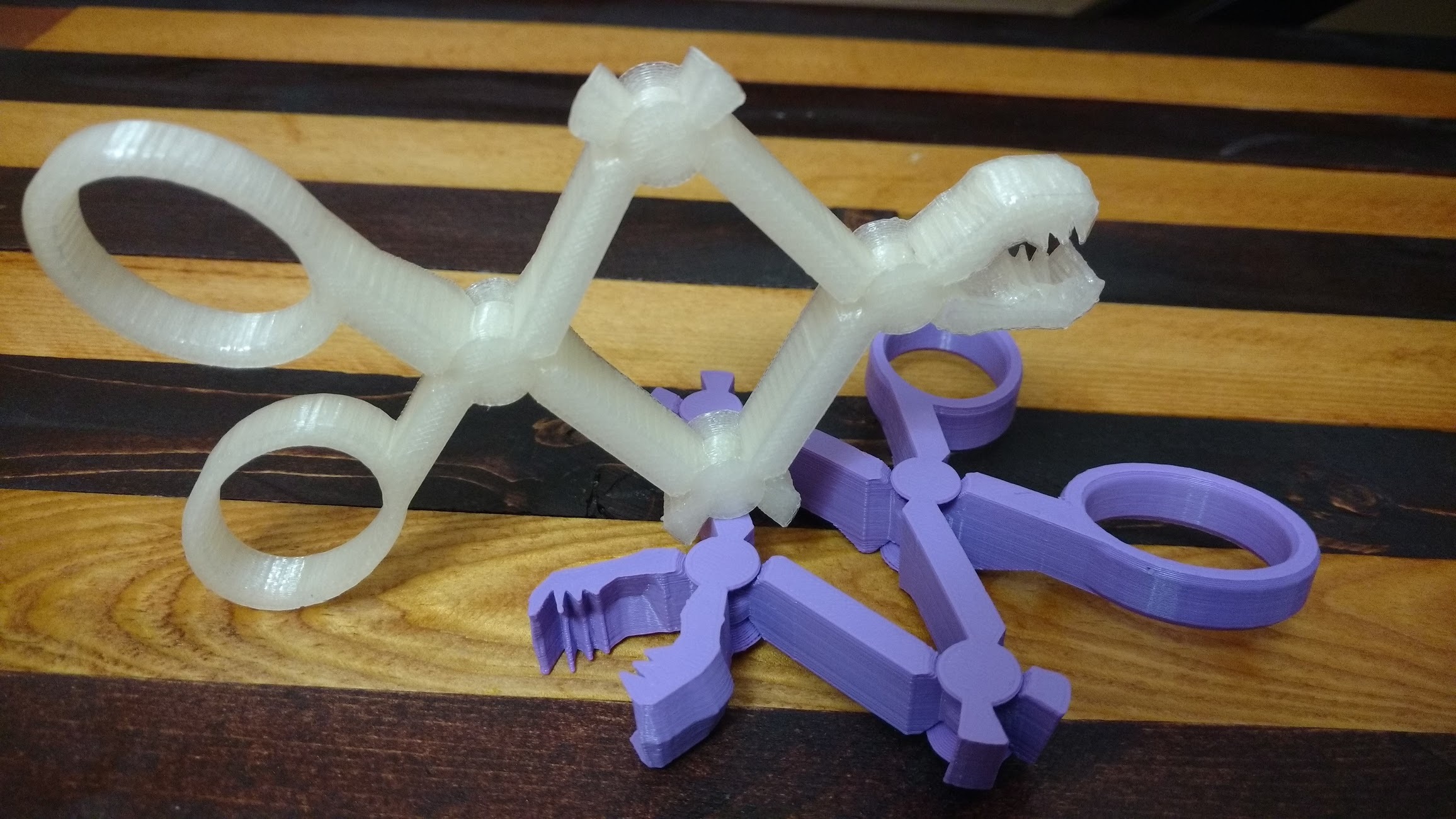

I printed both my samples finally these weekend and they turned out pretty nice.

Printed both PLA and PLA/PHA at 206C with Bed heated to 60C.

The print was run at variable speed. First layer and walls at 40 and infill at 90%. Everything printed smoothly with no jams or artifacts.

The mechanical scissors I printed have reasonably tight tolerances, Printed single walled at 70% infill and they both came out functional and strong. See attached:

Hi Dan, we want to thank you for the time you spent testing our filament and commenting about it. We are really happy with your results and would like to kindly ask you some important points as which brand is your printer machine, what was your speed printer settings for each material and also if you saw some resistance difference between the two different materials scissors.

Hi Mark,

Thank you so much for working with our material. We are more than happy with your results and with your Ultimaker filament comparison. I would like your permission to share your comments as an Ultimaker user and satisfied Meltink customer in our social media.

About our blend, it is the same to both filaments dimensions.

We’ll be waiting for your ABS test.

The ABS on the Makerbot proved just as difficult as the PLA. I have surmised that it must be something I’m doing (temp, leveling). I’ll keep trying, but as far as the 2.85mm, both were fantastic! Yes you can use any of my comments as you please.

I run a Makerbot Replicator 1 with a home made extruder assembly as the original is long worn out. The Lavender filament definitely has more flexibility to it, generally I find solid colour PLA filaments do over their translucent counterparts.

Makerware allows for variable speed at different parts of the print process I believe the settings for this print were:

First layer: 40mm/s

Walls: 40mm/s

infill: 90mm/s

bridging: 30mm/s

I did need to wait for the platform to cool before removing the parts, as right after the print everything was still too soft and the print would have deformed if I removed it immediately.

Printer Type: Reprap Prusa i3

Heated Bed: Yes

PLA

Design: NHL Stanley Cup - Dual Extruder (Pinshape) (on left) and a Stanley Cup that I designed myself (on right)

Extruder Temperature: 210 C

Bed Temperature: 60 C

Print Speed: 40 mm/s

Infill: 20%

Layer Height: 0.3 mm

Comments: Compared to the normal $15 PLA filament I normally use, it produces almost no bubbles and was very smooth. I also like the shiny finish to it.

PLA/PHA

Design: An iPhone 6 case with the Batman v. Superman logo that I created

Extruder Temperature: 240 C

Bed Temperature: 60 C

Print Speed: 15 mm/s

Infill: 20%

Layer Height: 0.3 mm

Comments: At first, this filament wouldn’t extrude at all. I ended up cleaning up my extruder and it finally worked. So once it worked, I printed out my iPhone 6 case. I would show you how it looks in it, but I’m taking pictures with my phone! Anyways, the filament is stronger than normal PLA and is more flexible. Also, it doesn’t warp at all. I am noticing that the layers of the phone case aren’t as smooth as PLA. I just printed the case again with my normal PLA filament and when comparing, see that the PLA/PHA case doesn’t look as smooth or glossy. But, this PLA/PHA filament is a great alternative to the smelly ABS, which is really good!

I have received my test filament. Sorry to say I will not have a chance to print anything by time the site goes offline. Thank you again for the opportunity.

Hi Caitlin,

I am so happy you could solve your printer problem. Thanks so much for your time, help and comments! We really appreciated them. Congratulations for your own design!

Good bay Pinshape Team and testers,

Even thought it is a sad moment for each of us we admired the Pinshape team for all your work and effort to help the 3D printing community. Personally ,I received great support in any of my inquiries . They will be difficult to forget and replace. I wish them all the best with their next project.

I would like to thank Karen, who help us to find you. She is very enthusiastic and was really helpful and quickly to contact you. We appreciate her diligence and advocacy to make this forum possible.

We are so grateful to everyone only for volunteering to test our new PLA/PHA filament. I really appreciated your support and generous assistance and comments. They will help us enhance our filaments and customer service with the main purpose of offering you the quality and service you are looking for.

If you do not mind if we shared your comments and pictures as satisfied Meltink users in our social media, please let us know. Also if any of you want to contact us you could do so through our email: [email protected].

We look forward to hearing from you at your earliest convenience and hope our filament will be a useful source for your future 3D printing projects.

Last but not least, we want to express our gratitude for all your spent time and work, we’ll be contacting you soon to offer a special discount if you are interested in acquiring any of our products.

Regards,

Meltink Team.

Thanks guys,

I have your contact information and will still contact you with my findings once testing is complete

Chris,

I finally got the Makerbot to print the 1.75mm filament successfully with the help of the following post:

Feel free to use anything I have posted.

I for one am certainly glad to hear Pinshape is staying in the game.

Thanks MeltInk for the opportunity to test your filament.