Hi Pinshapers!

Something that’s always been kicking around in my head has been to take what I enjoy, Motorsports, and some how incorporate it into 3D printing and educating people. The first thought I had was to reverse engineer a brake caliper in a way that it can be used to educate people and of course one that can be 3D printed.

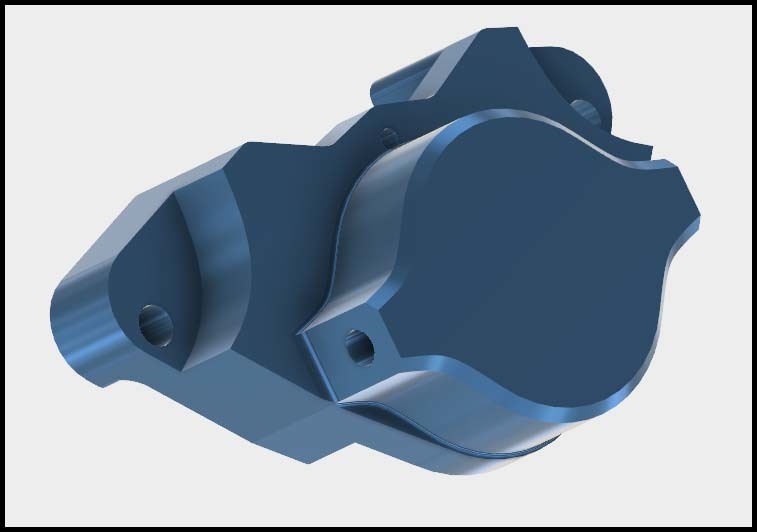

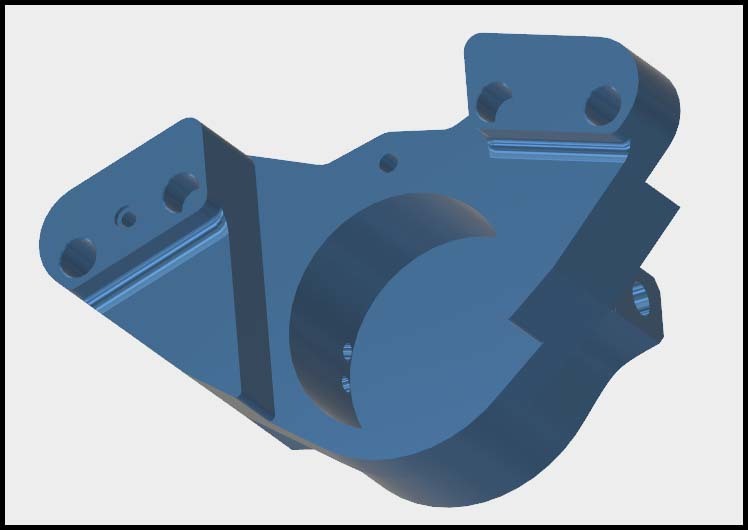

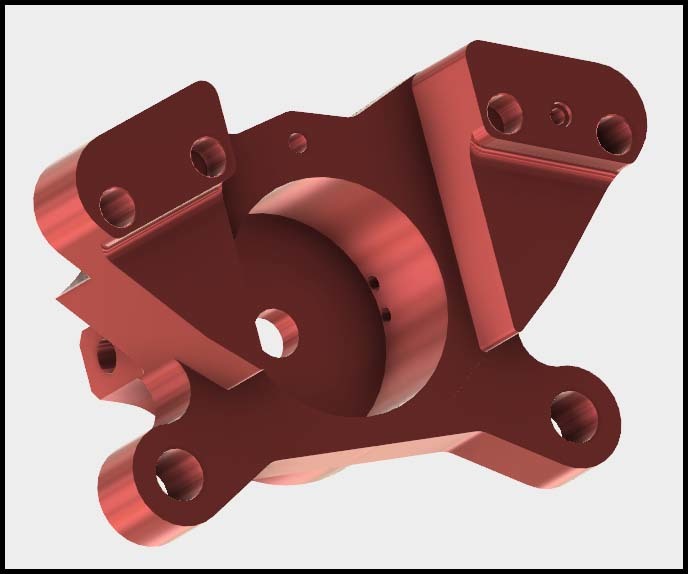

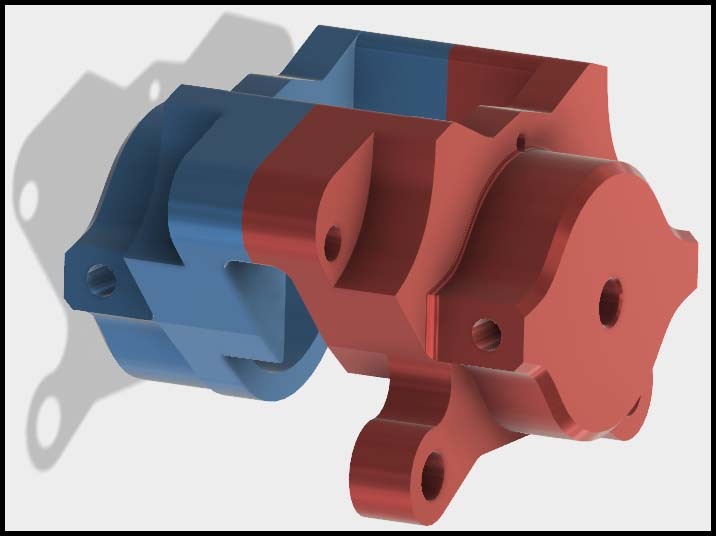

I’ve had a caliper in need of rebuilding for some time and I have chosen to disassemble that caliper so I can start producing a 3D model of it. Wilwood Dynalite Single - Billet That is an assembled view of the caliper. The caliper is billet aluminium in construction and contains 1 - 1.75" piston within each half of the caliper. The caliper also features dual brake fluid bleeders on each side of the caliper and 1 brake fluid inlet line. There is a small cross over port from side 1 to side 2. It is used to allow brake fluid to transfer from the main feed side to the 2nd side of the caliper, operating piston 2.

My initial intent is to produce a 3D printed brake caliper that features all components of the actual caliper except possibly the hardware [ex. mount bolts]. I can only print in harder materials at this time so there will be modifications to make this project practical for 3D printing. For instance, I will produce the seals in a matter that allows them to come out easier, not as tight as the original caliper has them. This will be the same for the piston. Fluid ports will also not be completely functional for this version however, I want to be able to show the start and finish of fluid ports so they can be discussed properly.

I also hope to produce a brief PDF document that can accompany the actual model and be used as guide lines for anyone wishing to discuss the caliper with a group or an individual.

Ill post some photos below. Id love to hear your feed back on this project. I am also very interested to hear if anyone as a good idea on how to fix the components to each other in a way that they can be disassembled without tools…Quick and easy!

Above is a photo showing each half of the caliper. In the middle, the piston recess’, you’ll also notice the cross over port on the left and right hand sides of the caliper half’s in the photo. The main fluid feed port is also seen on the right side peice.

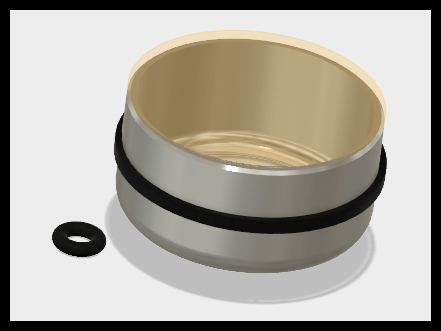

This photo shows the top side[face] of the piston, the piston seal and the small cross over port seal.

Another photo of the piston and seals. Notice the bottom side of the piston is concave, this is where fluid accumulates and then forces the piston outward into the brake pad and ultimately the brake rotor.

And finally, my current progress on the components. I have reproduced the piston, piston seal and the cross over port seal. The next step will be designing each side of the caliper.